There is a cost saving alternative to counter battening your roof when using fibre cement slates…

Man-made slates, better known as fibre cement slates, are becoming an increasingly popular choice of roof covering amongst architects, specifiers and roofing contractors across the industry, due to their attractiveness and smooth, easy fit design. These modern looking slates are classified as airtight or air impermeable roof coverings. Due to the nature of their uniform design, the ‘tight fitting’ of these slates significantly reduces the amount of passive, natural ventilation you might get from using more uneven products such as natural slates or concrete tiles.

Low vapour resistance (LR), vapour permeable or ‘breather’ membranes as they are often referred to in the industry (such as Protect VP400 Plus LR, VP300 and Zytec), are often the roofer’s choice of underlay, whether for a cold or warm pitched roof.

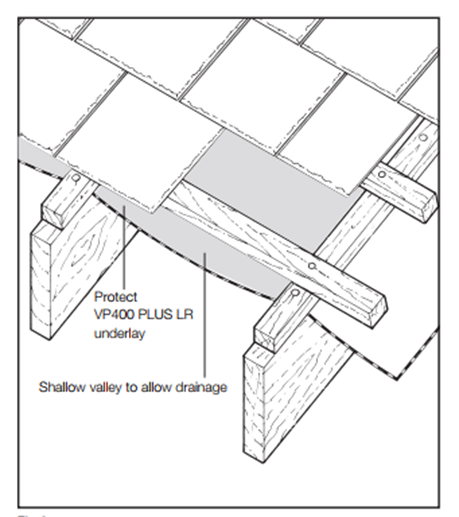

To be classed as a type LR or vapour permeable roofing underlay, the membrane has to achieve a water vapour resistance less than 0.25MNs/g and these underlays are designed to lower the risk of condensation forming in the roof space as they allow the water vapour to penetrate through the underlay, through the roof covering and out into the atmosphere. However, when an airtight roof covering is used alongside an LR membrane, ventilation openings above the underlay are required to conform to BS 5250 (management of moisture in buildings), using 25mm deep counter battens with a minimum free ventilation area of not less than 25,000mm²/m at eaves or low level and 5,000mm²/m continuous air gap each side of the ridge or at high level.

If counter battens are not installed when an LR underlay is used in conjunction with fibre cement slates, this will increase the risk of interstitial condensation forming on the underside of the roof covering, as the water vapour cannot pass through the external roof covering. This increases the risk of damage, including the potential decay of timber battens, rafters and possibly the corrosion of metals. Any roof with an airtight roofcovering and LR underlay would not be compliant to BS 5250 unless a ventilated counter batten space is included.

Counter battens above the LR underlay are required when an airtight roofcovering is used.

Save time and money…

An alternative cost-effective option that can save time and money is to install a high vapour resistance (HR) or impermeable non-breather underlay (such as Protect A1T3 Plus, A1 and Wunderlay) in place of an LR underlay when a fibre cement slate roof is being used. HR membranes have a water vapour resistance greater than 0.25MNs/g and were developed to overcome the disadvantages of traditional Type 1F and 5U felts. When using a HR underlay, BS 5250 does not require a ventilated counter batten space and the membrane is designed to prevent moisture from transferring through the underlay and reaching the exterior layers above the membrane. This approach would still require ventilation below the HR membrane at eaves or low level and airflow at ridge or high level to comply to the ventilation requirements stated in 12.5.2 ‘Cold pitched roof with HR underlay’ and 12.6.2 ‘Warm pitched roof with HR underlay’ within BS 5250, however would not require counter battening for ventilation.

In summary, if you use a HR underlay you do not need counter battens when using fibre cement slates, saving cost in labour and material. Ventilation can be achieved at high level and below the membrane at low level. If you use a LR underlay, counter battens are required together with a ventilated space above the underlay in accordance with BS 5250 management of moisture in buildings code of practice.

For any further technical requirements and ventilation guidance, please contact our technical team on technical@glidevaleprotect.com.

View Glidevale Protect Roofing Underlays brochure here