Q. Is additional ventilation required with Protect Viking Air?

A. The technology behind Protect Viking Air ensures top level performance is achieved in air and vapour permeability. The membrane delivers a high rate of uninterrupted airflow rate to eliminate the need for additional ventilation and reduces the risk of condensation in line with BS 5250.

The current BS 5250 guidance for an LR (vapour permeable) underlay used in a cold roof application is 5mm ventilation at ridge with either a well-sealed or normal ceiling. The NHBC permits the use of an air and vapour permeable roofing underlay such as Viking Air in a cold roof construction, without the requirement for additional ventilation based on the air permeability of the underlay providing suitable ventilation – at least the equivalent of a continuous 5mm high-level slot. This is referenced in the NHBC’s Technical Requirements R3 document:

‘where the air permeability of the underlay can be shown to provide suitable ventilation, i.e. at least the equivalent of a continuous 5mm high-level slot, NHBC will accept that underlay without the need to provide any further ventilation.’

Protect Viking Air, categorised as an air and vapour permeable roofing underlay, can achieve the equivalent of 5mm high level ventilation and can therefore be used in cold roof construction without additional roof space ventilation.

In cases where there is an impermeable roof covering installed such as fibre cement or metal tiles, there will be a requirement for ventilation. In these cases, the batten space needs to be ventilated with 25mm counter battens and ventilation provided – 25,000mm²/m at eaves or low level and 5,000mm²/m at ridge or high level. Alternatively, if closed jointed sarking with no gaps is used directly beneath the underlay, this will restrict the underlay’s permeability and airflow within the roof, so ventilation will be required. Details are included in the Protect Viking Air brochure – view here.

Q. Is a separate air and vapour control layer (AVCL) required with Protect Viking Air?

A. Whilst the installation of a separate AVCL is not a mandatory requirement when Protect Viking Air is installed on the roof, Glidevale Protect does recommend the use of an air and vapour control layer on the warm side of the insulation, where this is achievable.

If the specification demands a belt and braces approach with a well-sealed ceiling, this offers benefits over an unsealed ceiling. As stated in BS 9250, the code of practice for design of the airtightness of ceilings in pitched roofs, a well-sealed ceiling can reduce air and vapour transmission into the roof by 70% which will save about 8-10% of the energy consumed in a typical house. Delivering this airtightness means energy efficiency is maintained and can help reduce overall energy bills for the homeowner.

If there are gaps in the ceiling such as around loft hatches, service pipes and light fittings, air and vapour may flow from the living area to the loft space. With heat and moisture passing through the gaps, this not only contributes to energy loss from the building but also creates a risk of warm air from the property meeting cold, which would result in the dew point being achieved and then ultimately a risk of condensation in the roof space. The ability to seal at this junction is down to the practicability of the design and the standard of workmanship involved in installation.

BS 5250, the code of practice for the control of condensation in buildings, recommends that air leakage through ceilings should be minimised. The BS 9250 standard also provides guidance on methods that can be used to meet the “well-sealed ceiling” requirements defined in BS 5250 for cold and warm pitched roofs.

To support the above guidance in BS 5250 and BS 9250, Glidevale Protect has a full range of products that can work hand in hand with Protect Viking Air and all Glidevale Protect roofing underlays, ensuring buildings are designed and constructed using the fabric first approach with the aim to minimise energy consumption. This includes both reflective and non-reflective air and vapour control membranes, sealing tapes and loft hatches which are designed to support the control of condensation and heat loss at this critical junction. The installation of these products can also improve the roof structure’s overall thermal performance, potentially reducing the thickness of insulation within the ceiling whilst achieving strict air tightness levels and low U-values. These are the common demands and expectations for a specifier in today’s global environment where climate change is a significant challenge within building design. As specifications become even more onerous and Building Regulations are being updated, the key is for the building fabric to help address the measures to meet the net zero carbon emissions targets by 2050.

The Glidevale Protect Technical team can provide additional support and reassurance to specifiers. By supplying the proposed full build-ups, whether for cold or warm roof, U-value calculations and condensation risk analysis can be undertaken to include Viking Air or alternative Glidevale Protect roofing underlays as well as air and vapour control layer layers on the warm side of the insulation.

Q. Is Protect Viking Air watertight?

A. Protect Viking Air achieves a Class W1 rating when tested to BS EN 1928, modified by BS EN 13859-1, ensuring it is fit for purpose like all other Glidevale Protect roofing underlays. In addition, as part of the Declaration of Performance, the product achieves a resistance to water penetration (hydrostatic head of water resistance) of >1m to EN ISO 20811. This ensures the product can be used as a temporary roof covering before the main roof covering is installed. In accordance with good building practice, Protect Viking Air is to be covered as soon as possible after installation and preferably not more than one month after initial exposure. For further clarification on these exposure times or if the exposure period exceeds one month then advice must be sought from the Glidevale Protect technical department at technical@glidevaleprotect.com

In addition, to further enhance the product’s water penetration resistance, Viking Air is hydrophobically treated to repel water and provide additional water shedding properties, thereby preventing moisture ingress.

Q. How permeable is Protect Viking Air?

A. Protect Viking Air has been tested to BS EN 12114 with the underlay allowing for 78.71m³/m²/hr of air permeability @ 50 Pascals, achieving the best performance in the air permeable underlay market. The water vapour resistance has also been tested to BS EN ISO 12572, Method C and allows 0.04 MNs/g or 0.008 Sd (m) of vapour resistance, so is classed as a vapour permeable underlay with low resistance (LR), ensuring the product also provides the best vapour permeability in the air open underlay category.

Q. What is the colour and construction of the roofing underlay?

A. Protect Viking Air is beige in colour on the upper surface which stands out from other underlays in the Glidevale Protect portfolio. The product features Viking Air branding printed in black alongside a 150mm printed overlap line. The underlay is printed with a unique grid design for ease of identification and to assist with cutting on site. The membrane has a white lower surface and a middle core layer which utilises melt-blown technology to ensure the higher air and vapour permeability.

Q. Are any accessories required with Protect Viking Air i.e. sealing tapes etc?

A. Protect Viking Air is simply fixed with stainless steel staples or clout head nails and does not require any tapes to seal the laps. When installed over counter battens or rafters, the product should be laid with shallow drapes up to a maximum of 15mm to ensure moisture can drain away safely and create a fortuitous ventilation path (which the use of tapes will prevent). The use of a Glidevale Protect OFV eaves skirt can be specified as part of the overall roofing package.

Q. In which wind zones is Protect Viking Air compliant?

A. Protect Viking Air can be used in wind uplift zones 1-4 at the widest batten gauge of 345mm, providing extensive coverage in the UK and throughout Ireland and is superior to any alternative air permeable underlay product on the market. At 310mm batten gauge or when used on sarking board, Viking Air has unrestricted use, being suitable in wind uplift zones 1-5. Testing has been conducted in compliance with BS 5534 and the underlay can withstand a wind load of 1569 Pa at 345mm batten gauge, which borders on zone 5 performance (1600 Pa). For 310mm batten gauge, a 2121 Pa wind load resistance is achieved.

Q. Is Protect Viking Air independently, third party certified?

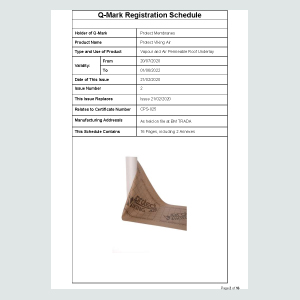

A. Like all Glidevale Protect roofing underlays which are tried, tested and have been regularly installed over many years, Viking Air’s performance is backed up by full, third party, independent certification from BM TRADA’s Q-Mark Registration Scheme, giving confidence and reassurance in specification. BM TRADA as an independent certification body is UKAS accredited, ensuring third party assurance is given to British, European and International Standards. This provides confidence that all Glidevale Protect certified roofing underlays are independently verified to be fit for purpose for their intended application. Certification involves initial type testing and factory production control audits with certification maintained through scheduled process checks.

Viking Air’s BM TRADA Q Mark Registration Schedule and Certificate are available on this website for download or can be sent directly from Glidevale Protect’s Technical Team at technical@glidevaleprotect.com. The schedule demonstrates that Viking Air can be used in a cold roof construction without additional roofspace ventilation as accepted by the NHBC. The product also holds CE marking through its DoP (Declaration of Performance) which is featured on the product roll label.

For a full Viking Air specification clause click here or contact Glidevale Protect’s technical team on 0161 905 5700 or technical@glidevaleprotect.com