Client

Pears Roofing

Project Overview

Pears Roofing in Blackpool opted for Protect Membranes Ltd and their range of Roofing Underlays to supply the Millers Green Project in Heysham, Lancashire. The project consisted of 54 new build houses and they had the option to choose from a range of different roofing underlays currently in the market.

The Challenge

With Heysham being a large coastal village facing the Irish Sea, any project undertaken requires an underlay that will withstand extreme weather conditions that can prevail especially in the winter and be able to absorb the wind loads generated by the unique topography of the location.

The Solution

Discussing the changes in BS 5534: 2014 with Pears Roofing, Protect Membranes were able to offer them the tried and tested solution of an ‘unrestricted use’ Vapour Permeable underlay in the form of VP400 Plus LR, more than capable of tackling the detrimental weather conditions blown in from the Irish Sea.

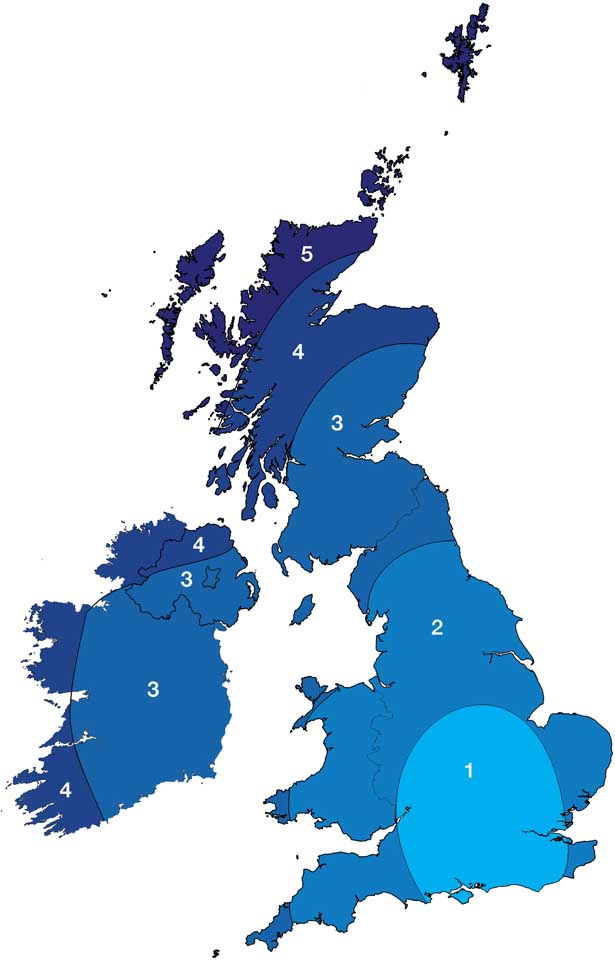

Protect VP400 Plus LR is a superior and highly vapour permeable roofing underlay for the use in warm and cold pitched roof construction, helping to prevent harmful condensation risk in the roof space in accordance with BS 5250: 2011. A complete weatherproof barrier with excellent nail tear and tensile strength properties, VP400 Plus LR is suitable for zones 1-5 at all batten gauges without the need to tape and seal the underlay laps.

Protect Membranes have been at the forefront of roof underlay development and testing to help manage wind uplift in roofs since 2004, and are able to offer complete guidance in terms of the correct specification of the roof underlay.

All Protect underlays are independently tested and certified by BM Trada with the required zone mapping on the roll label.

For more information on the solution used in this case study, please contact us at info@glidevaleprotect.com or call us on +44 (0) 161 905 5700.

Products used

Protect VP400 Plus LR vapour permeable underlay

View productView full case study

DownloadCustomer testimonial

Pears Roofing chose Protect Membranes over other manufacturers membranes, because a roofing underlay that was ‘suitable for the job’ was key to the whole project. The decision to specify Protect VP400 Plus LR was not only due to its strength, vapour permeability and price, but was the preferred choice as it worked in all zones at all batten gauges without the need to seal with tapes.

Chris Pear, Director for Pears Roofing