Q. Where are stepped cavity trays used?

A. A stepped cavity tray is used where a sloping roof abuts an external wall. Below the roof line the external leaf of brick or blockwork becomes an internal wall. They are also required where the cavity wall is bridged, e.g. by a lintel or ducting.

Q. Why are cavity trays required?

A. Brick and block are porous materials; therefore, water often penetrates through the outer leaf of the external wall into the cavity space and trickles down the internal face of the inner leaf. It is therefore necessary to prevent this moisture from entering the building by using a cavity tray to catch the moisture.

NHBC Standards for ‘External masonry walls’ section 6.1-D6 (a) and BS 8215 ‘Design and installation of damp proof courses in masonry construction’ specifically recommend the use of preformed abutment cavity trays.

Q. How does the cavity tray disperse the water?

A. Unlike other manufacturer’s cavity trays that require the fitting of weeps to the bottom catchment tray, all Glidevale brickwork trays have an integral bed weep allowing water to safely drain to the outer face of the external wall at each stepped tray.

The Glidevale cavity tray range has been appraised under BS EN 9001, giving an independently audited and monitored assurance that the products are designed to meet their intended purpose.

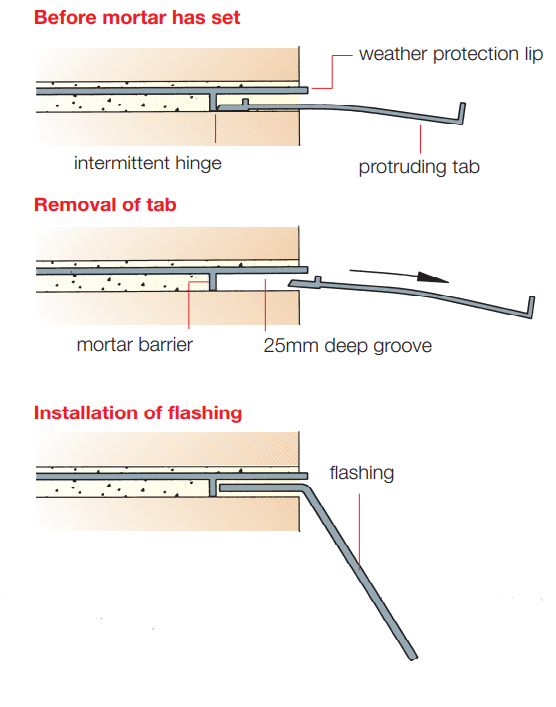

Q. How do I fit lead to an unleaded tray following installation?

A. Glidevale brickwork trays have a unique fleximouth mortar barrier on the lower leading edge of the tray which is kept attached during installation. Once installed and the mortar has set, pull the protruding tab out. This will leave enough room to fit the lead flashing without the need to rake out the joint. We advise to also seal with mastic.

Q. I have a 150mm cavity, will the cavity trays be suitable as they will not reach the inner leaf?

A. A self-supporting cavity tray, such as Glidevale’s, must cover half of the open cavity. Typically, a 150mm cavity would have 50mm of insulation fitted to the inner leaf of the cavity, once this is fitted Glidevale cavity trays would be covering the required depth.

Q. Should I use long or short lead flashing? Which thickness of lead would I need?

A. The length of lead flashing is dependent on the roof covering and pitch. When using a profiled tile then long lead is advised, conversely if using a flat tile or slate covering then short lead would be best. Glidevale cavity trays are supplied with code 4 lead as standard, other thicknesses are available by request.

Trays are also available with factory-fitted Protect AluFlash flashing; a lightweight, aluminium based alternative to lead.

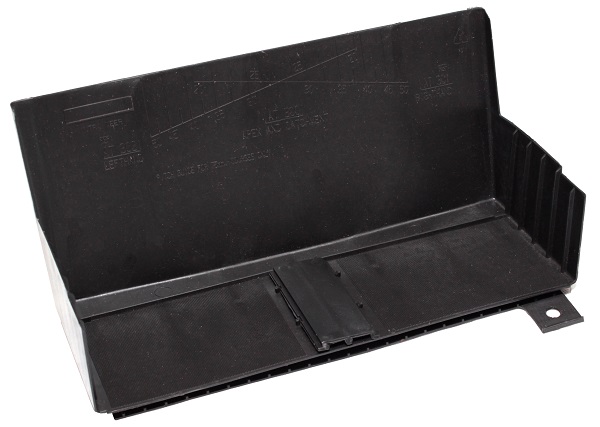

Q. Can the cavity trays be set to the correct pitch and fixed without a dummy truss being fitted?

A. On the back of Glidevale stepped cavity trays there is a printed pitch finder, which allows our trays to be fitted without the use of a dummy truss. Further information is available by contacting our Technical Department on 0161 905 5700.

Q. How do I know which cavity trays to use?

A. Glidevale offers a free quotation service and will provide a full list of products required for the abutment. The Technical team will require elevation drawings of the property, showing the all abutments. Please send any enquiries and drawings to technical@glidevale.com

Q. What other types of cavity trays can you supply?

We can also provide a range of low and high level trays including horizontal, bullseye, lintel, chimney and parapet trays, as well as bespoke trays to your specification. Please contact our Technical team for more information at technical@glidevale.com or on 0161 905 5700.

For further information regarding our full cavity tray range please find our literature here.