Client

Seven Oaks Modular Ltd / Hale Construction Ltd

End Client

Gwalia Housing, part of the Pobl Group

Main Contractor

Morganstone

Project Overview

With a completion date in 2019, this new build development offers a mix of 41 affordable homes all of timber frame construction, including two and three bedroom houses, one and two bedroom apartments and two bedroom bungalows.

Based on the site of the former Four Seasons Social Club in Swansea, Wales, the project required the main contractor Morganstone to overcome engineering problems such as shallow mine workings, poor ground and existing structures on-site to deliver a scheme that not only met the need for affordable housing with a modern living space but was in keeping with local architecture, had a traditional feel and regenerated the area.

The Challenge

Timber frame specialist Seven Oaks Modular Ltd was awarded the contract to construct wall panels in their factory for this development, followed by delivery and installation on-site with the need to ensure the client met the target U-value of 0.19W/m2K for the wall. With key challenges being the requirement to reduce material waste in the factory and to value engineer without severely impacting labour cost, Seven Oaks Modular sought the expertise of Protect Membranes to deliver an innovative solution through the use of low emissivity, reflective membranes to meet these objectives.

The Solution

The Solution

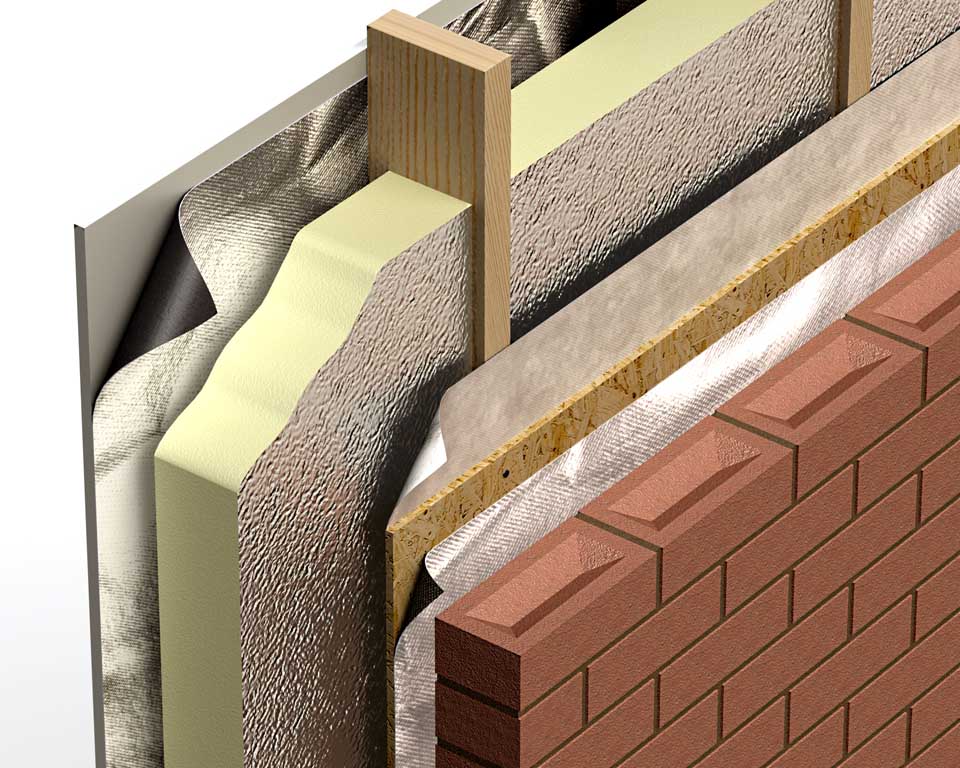

Following detailed technical discussions, a series of U-value calculations to meet the target 0.19W/m2K U-value was undertaken by Protect’s technical team along with a condensation risk analysis. The proposed wall type was adapted to incorporate Protect TF InterFoil, a vapour permeable, reflective membrane installed within the panel on the back of the sheathing board on the cold side of the insulation, with the foil facing into an airspace to ensure low emissivity performance. A combination of Protect’s reflective, external breather membrane TF200 Thermo facing a 50mm unventilated cavity and the reflective, internal vapour control layer Protect VC Foil Ultra facing into a 25mm still airspace helped to create a radiant barrier. The proposed solution was agreed by Seven Oaks Modular and resulted in enhanced thermal efficiency and reduced energy loss. The use of three reflective membranes also enabled important insulation cost savings to be made as the PIR board was able to be reduced in thickness by 40mm. The overall total wall footprint also remained the same thereby keeping within the original specification, whilst in the factory, cost savings were made by reducing production waste. The new build-up allowed both Protect TF200 Thermo and Protect TF InterFoil to be precision fitted in the factory under controlled conditions, with Protect VC Foil Ultra fixed on-site.

The three membrane solution used on the wall construction gave a cumulative benefit on the wall’s thermal performance:

Protect TF200 Thermo – this reflective, insulating breather membrane used externally features a high purity aluminium foil surface with a thermal resistance R-value of 0.77m2K/W (including printed logos) to deliver a 328% improvement in thermal performance (horizontal wall heat flow) when compared with a standard membrane with no special treatment using a minimum of a 20mm still airspace.

Protect TF InterFoil – this vapour permeable, reflective and insulating breather membrane used on the inside of the timber frame panel forms a radiant barrier when used facing into a still airspace. In the same way as Protect TF200 Thermo, this is a low emissivity, vapour permeable product with a foil surface to block infra-red radiation and achieve a thermal resistance R-value of 0.77m2K/W facing into a minimum 20mm cavity.

Protect VC Foil Ultra – this reflective air and vapour control layer used on the warm side of the insulation faces into a service void to ensure condensation control and provides excellent air and vapour resistance. With a thermal resistance R-value of 0.78m2K/W, this insulating membrane gives an improvement of 333%in thermal performance (horizontal wall heat flow) when compared with a non-reflective vapour control layer using a minimum of a 20mm still airspace.

The pitched roof structures for the Four Seasons development were also constructed by Seven Oaks Modular and incorporated branded, green Protect TF200, an external breather membrane applied to the outside of the spandrel panels to ensure water resistance and vapour permeability thereby significantly reducing the risk of condensation. The roof tiling for the development was subcontracted to specialist roofing contractor M A Hartley Roofing Contractors Limited in Swansea, with Protect VP300 specified and installed as a vapour permeable, airtight roofing underlay to provide a secondary line of defence against wind driven rain and snow, minimising the risk of condensation in the roof space. The product’s wind uplift resistance meets Zones 1 to 3 using 345mm batten gauge to BS 5534:2018, suitable for this location.

For more information on the solution used in this case study, please contact us at info@glidevaleprotect.com or call us on +44 (0) 161 905 5700.

Products used

Protect TF200 Thermo insulating breather membrane

View productProtect TF InterFoil

View productProtect VC Foil Ultra insulating vapour control layer and air barrier

View productProtect TF200 breather membrane

View productProtect VP300 vapour permeable underlay

View productView full case study

DownloadCustomer testimonial

The use of Protect’s full reflective membrane system for the Four Seasons scheme enabled us not only to value engineer this project but ensure a robust solution that provided affordability to the client. The innovative application of membranes offering low emissivity within unventilated cavities was easy to incorporate into our timber frame panels at the factory, ensuring the structure retained thermal efficiency and met our target U-value. We are now offering this build-up as a standard wall type to our customers.

Warren Rowlands, Senior Designer at Seven Oaks Modular.